Laminate Analysis…Upgrading with Reduced Risk

Until recently, the pleasure boat industry has tended towards oversimplification in the engineering of fiber reinforced plastics (FRP). The reason? Local loads on small boat hulls are not well defined and, in many cases, are approximated. A thorough engineering laminate analysis of small boat structures is seldom justifiable from a cost standpoint.

Research often involves deriving a boats scantlings either by experience or with empirical methods and applying these philosophies to later designs. The danger in such a process is the possibility of perpetuating either an overly-conservative design, or a structurally unsafe one. Faced with an ever-growing choice of advanced composite reinforcing materials, reinforcing forms, core materials and resins, todays designer or engineer should be looking at sharpening their laminate analysis skills. Fortunately the range of options for understanding and predicting laminate behavior is growing to keep pace with materials choices.

In many production shops, laminate schedules have remained relatively stagnant over the past 20-30 years with alternating layers of 24 oz woven roving and 1-1/2 oz mat being the norm. If a core is used at all, it is usually plywood, and then only in the deck. Structural grids, too, are still inevitably plywood.

However, with the advent of composites came the freedom for engineers to select structural arrangements for their most effective use and to take advantage of a vast choice of materials and processes. This choice starts with conventional materials such as solid E-glass and polyester resin laminates in a wet lay-up. It extends to the use of advanced sandwich laminates using S or R-glass, carbon fiber, Kevlar, hybrids, balsa, foam and honeycomb cores, epoxy and vinyl ester resins in either a wet, prepreg, or resin-infused laminate. Subject to cost restraints, these choices give designers the freedom to use their imagination and engineering expertise as well as providing a unique challenge in design. This challenge is to make the most efficient structural and economic use of the materials.

If properly engineered, advanced composite structures will have a higher strength-to-weight and a higher stiffness-to-weight ratio. Effective use of less expensive reinforcement with limited use of advanced composites can produce boats with structural efficiency approaching that of well-engineered advanced composite hulls. An typical shell or deck laminate will be designed for tensile, compressive, impact and fatigue loading and have strength and elastic properties in each in-plane-direction to match the loading in that plane. Therefore each ply in the laminate is used as efficiently and effectively as possible. This can be attained with a limited number of material blends using some combination of Kevlar, carbon, S or R-glass, E-glass, balsa, cross-linked foam cores, linear foam cores, and honeycomb cores.

The quest for ever lighter, structurally sound hulls is not attained simply by using advanced composites, and the complexity of composite analysis does not readily lend itself to easy solutions. With the use of composites there emerge new demands, new considerations and new pitfalls. Most of the issues that arise in the design stage are related to the fact that advanced composites require a more detailed and comprehensive approach in structural design. The characteristics of advanced composites that allow them to be so effectively engineered, can conversely make them both prone to misuse and much more unforgiving if improperly used.

To aid in the design process, many advanced tools have been developed for today’s yacht designers, enabling them to produce strong, lightweight and economical boats with a high degree of confidence in their structural integrity. These tools, such as composite analysis programs, finite element analysis programs, and advanced testing facilities, have until recently only been within the financial grasp of the aeronautical and automotive industries. Finite Element (FE) analysis and physical testing usually require a much higher level of commitment in time and money, but relatively inexpensive computer programs are now available that predict the ultimate strength and stiffness of a cured laminate from the cured properties of the plies making up that laminate.

In selecting or relying on such a program it is essential to determine if the program has been verified and calibrated by comparing program predictions with the results of cured laminate tests. It is also important to understand the limitations of these tools when engineering a composite structure and to utilize this information with a high degree of common sense. The following highlights some of the commercially available programs being used by the marine industry:

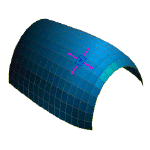

CompositePro – is produced by Peak Innovations. It is a full-featured Windows based package which includes a micro mechanics module based on rule-of-mixtures, cylinder model and Chamis methods. It allows the user to select from a standard library of materials or input their own values. A laminate module allows the user to lay up any combinations of plies at any angle and calculates laminate strength, extensional and bending stiffness based on either “first-ply” failure, a “progressive-ply” option, and the Classical in-plane laminate theory. A laminated plate module, based on Navier plate solutions, calculates bending moments and deflections for simply-supported uniform or concentrated loaded plates. A sandwich plate module allows the user to select different core materials and to calculate sandwich buckling, panel deflection, and face wrinkling stresses. A tube/beam module calculates bending, torsional, and axial stress for a variety of cross-sections using basic beam theory and NASA SP-8007 cylindrical stability formulations. A utility module converts volume and weight fractions, and calculates ply thickness for filament winding and fabric materials. Although used by several boat builders, this program is not specifically aimed at the marine industry, but has definitely cornered the market on “bang-for-the-buck” composite analysis software (CompositePro – $595).

CShell/CLam – These programs have been developed by Robert Schofield and Javier Munoz for R.A. Schofield Naval Architects. CShell is a state-of-the art, Windows and DOS-based design system for ships and small craft and uses the American Bureau of Shipping (ABS) guides to calculate scantlings. It takes hull geometry, displacement, service criteria and the frame/stringer arrangement and calculates the hull structure requirements. CLam is a composite design module for creating a laminate and comparing it with ABS. This module allows the user to interactively design a laminate with different ply and core types and assess structural stiffness, flexural strength, and shear strength. Up to five different laminates can be compared in terms of strength, weight, and cost. CLam is also offered as a stand-alone program to design composite laminates and evaluate their structural properties. The program uses laminate plate theory and is based on first ply failure. The program utilizes a standard data base which can be easily built on. Clients include such heavyweight powerboat companies as Sea Ray, Wellcraft, 4 Winns, and Cobalt Boats, amongst others (price – $2000).

SHIPDES/COREDES – This program, developed by Deborah Burman and David Jones for Sigma Software Inc., has been written specifically for the marine industry and is targeted at the naval architect and boat builder. It is a comprehensive DOS-based composite analysis program (the Windows version is in the works). It is capable of predicting panel stresses, hull panel response, deflection, and stiffener and bulkhead response. It also assists the builder in optimizing composite structures. It includes nine user-friendly design modules which can be run independently. The program can be used to perform a wide range of composite analysis including: single-skin panels using a summation method to calculate for flexural and tension stresses; sandwich panels using the “elastic foundation theory” calculating for compression, tension, and core shear in flexure; panel deflection at yield and the critical stress factor; plus stiffener calculations for section modulus, moments, and deflections. The program also has a library of material properties, and has a unique technology transfer program which teaches the user to design structures for composite hulls (price $1750).

VectorLam – is written by Stephen Fitzgerald for Practical Composites, Inc. It is a spreadsheet program which can be easily run in an Excel, Lotus, or Quattro Pro environment. It is extremely user-friendly and the learning curve should only be a few hours. The math is based on laminate plate theory, and the properties it calculates include: fiber content by weight or volume; laminate thickness; composite density; resin, fiber and total laminate weight; in-plane shear modulus; in-plane stiffness; flexural stiffness; tensile strength; flexural strength; (Laminate Analysis cont.) Poisson’s Ratio; and plate bending stiffness. Because of the spreadsheet format the program is easily customized and expanded and also allows the user to cut and paste results into reports and technical documents. It also comes with a cost estimating feature and a standard library of materials which can be used for hybrid laminates. The software, as of yet, is not commercially available, although a complimentary copy is available through Johnstone Industries which is a supplier of FRP materials.

If the designer is faced with undertaking a more detailed structural analysis, and budget is not an issue, finite element analysis will yield much more extensive information. FE programs typically run anywhere from $4000 and up, depending on how sophisticated they are. But the expense doesn’t stop there. It takes a lot of time and effort to accurately model a part in 3-D, particularly if it has a complicated geometry. Running the analysis is actually the easy part of the process. I usually out-source this type of work, not wanting to be faced with the expense or the time needed to overcome a steep learning curve in mastering an FE program. The major advantage of finite element analysis is that the programs can run a variety of load conditions for both static and dynamic states and accurately predict the response of a laminate. Although quite sophisticated, they too rely on a database of materials to produce meaningful answers and usually require supplemental information from the physical testing of a particular laminate.. There are several PC based programs on the market which include Algor, Rasta, AutoDesign 3.3, and Inertia.

Although mechanical properties of various cured, composite reinforcing plies are available from manufacturers, they are often accompanied by a disclaimer as to unsuitability for design purposes. There is ample cured laminate property data available for standard laminates, but they comprise a very limited number of different ply types. Unfortunately, mechanical property test data for cured laminates, comprising combinations of advanced reinforcing plies, is in serious shortage or is unavailable due to the proprietary source of the information. Other sources, within the public domain, include aerospace and military libraries such as the MIL-HDBK 23, Volume 2 which can be downloaded via the Internet from www.ccm.udel.edu/army/PMC/ . There’s also a wealth of information and innovative ideas in publications such as High-Performance Composites magazine.

The other resource available to designers is physical testing. As mentioned above, the only way to accurately assess the response of a composite laminate to the variety of load conditions it may be subject to in a marine structure, is to physically put it through a series of tests to determine its strength characteristics. That in itself presents further problems the designer must consider. The physical characteristics of a laminate are dependent, to a large degree, on the skill of the individual laminator and tend to vary widely for a given type of laminate. Causes of variation in strength are many; fiber-to-resin ratio, the quality of the raw materials, rate of cure, temperature and humidity during lay-up, misalignment of reinforcement and the distribution of the resin through the laminate. For this reason, all test laminate samples, or coupons, should be manufactured to an industry-recognized standard in the yard where the boat will be built and not in the sterile environment of a laboratory. There are number of facilities capable of conducting composite testing in the US, among them the Baltek Corporation, ETC Laboratories, OCM Test Laboratory, Plastics Technology Laboratories, Inc., Sigma Labs and Structural Composites. All have a wealth of practical and theoretical knowledge to complement the services they offer.

If the designer or builder wants to out-source the scantling specifications for a boat, there are many firms that specialize in engineering composite structures. Besides being able to utilize all the above tools, they have an extensive repertoire of past and proven projects they can draw from. This group of consultants has a broad international base and includes; ATL Composites, D.E. Jones & Associates, Inc., High Modulus, Dirk Kramers Inc, R.A. Schofield Naval Architects, SP Race Boat Group, Van Gorkom Yacht Design LLC, Burke Design.

So what is the marine industry to do in order to further the development of composite analysis? By building a comprehensive database of mechanical properties that is broadly available, the industry would not only be advancing the science of marine composites by encouraging an exchange of information, but it would be creating a safer and more cost effective environment. A materials library such as this would take much of the guess work out of the way composites (Laminate Analysis cont.) are engineered and have the effect of raising structural standards and lowering costs, particularly in the production boat markets. How do we build this library and who would administer it? There are several organizations working towards compiling this information from physical testing, among them the Society of Naval Architects and Marine Engineers (SNAME), the Society for the Advancement and Materials Process Engineering (SAMPE), and the composite engineering departments at the Universities of Delaware, Massachusetts (Lowell), Maine, and Southern California.

However, this compilation is at present just a mere trickle of what it should be and is often not in an usable format for design purposes. The opportunity exists for the material suppliers, testing labs, builders, and designers to work together to establish a set of realistic test sample preparations that emulate the boat yard environment. The results from testing these samples would be contributed to an industry database administered by a representative organization like the National Marine Manufacturers Association (NMMA), the Composite Fabricators Association (CFA), the American Bureau of Shipping (ABS), or the American Boat and Yacht Council (ABYC). All aspects of the marine industry can benefit from this type of shared resource. Builders and designers can benefit by creating better engineered, more efficient and cost effective products. Testing labs and material suppliers can benefit by being able to develop new materials and new processes. These factors alone will have the overall effect of stimulating the marine industry and advancing the science of composite analysis.

A Listing of Related Companies & Organizations:

Algor Inc.

150 Beta Drive

Pittsburgh, Pennsylvania 15238-2932, USA

Tel: (412) 967-2700

American Bureau of Shipping (ABS)

16855 Northchase Drive

Houston, TX 77060, USA

Tel: (281) 877-6732

American Boat and Yacht Council (ABYC)

Third Street, Suite 10

Annapolis, MD 21403, USA

Tel: (410) 990-4460

American Composites Manufacturer’s Association

1010 North Glebe Rd. Suite 450

Arlington, Virginia 22201, USA

Tel: (703) 525-0511

American Society for Testing & Materials (ASTM)

100 Barr Harbor Drive

West Conshohocken, Pennsylvania 19428-2959, USA

Tel: (610) 832-9721

ATL Composites Pty. Ltd.

P.O. Box 2349

Southport, Queensland 4215

Australia

Tel: +61-7-5537 7636

Baltek Corporation

10 Fairway Ct.

P.O. Box 195

North Vale, New Jersey 07647, USA

Tel: (201) 767-1400

Burke Design

31 Dimond Avenue

Bristol, RI 02809, USA

Tel: (401) 254-6113

www.burkecompositeengineering.com

D.E. Jones & Associates, Inc.

607 Apalachee Circle N.E.

St. Petersburg FL 33702-2721, USA

Tel: (727) 577-9976

Det Norske Veritas (USA)

One International Boulevard, Suite 1200

Crossroads Corporate Center

Mahwah, NJ 07495, USA

Tel: (201) 512-8901

Diab Group

315 Seahawk Drive

DeSoto, Texas 75115, USA

Tel: (214) 228-7600

Dirk Kramers & Associates

60 Nonquit Lane

Tiverton, Rhode Island 02878-4814, USA

Tel: (401) 624-3804

Fax: (401) 624-8665

ETC Laboratories

297 Buell Road

Rochester, New York 14624, USA

Tel: (585) 328-7668

Fiberglass Industries Inc.

RD #5 Edson St.

Amsterdam, New York 12010, USA

Tel:(518)842-4000

High Modulus

9-11 Rothwell Avenue

North Harbour,

Auckland, New Zealand

Tel: +64-9-415 6262

Fax: +64-9-415 7262

High-Performance Composites

Ray Publishing Inc.

4891 Independence St., Suite 270

Wheat Ridge, Colorado 80033, USA

Tel: (516) 756-2600

Fax: (516) 756-2604

Johnstone Industries Composite Reinforcements Inc.

P.O. Box 10

3503 Lakewood Drive

Phenix City, Alabama 36868-0010, USA

Tel:(334) 291-7704

Fax:(334) 291-7743

Knytex

1851 Sth. Seguine St.

New Braunfels, Texas 78130, USA

Tel: (210) 629-4009

Fax: (201) 629-2540

Lloyds Register of Shipping

71 Frenchurch St.

London EC3M 4BS

England

Tel: +44-181-709-9166

Fax: +44-181-488-4796

Tel (USA): (212) 425-8050

National Marine Manufacturers Association (NMMA)

200 E.Randolph Drive, Suite 5100

Chicago, Illinois 60601, USA

Tel: (312) 946-6200

Fax: (312) 946-0388

Nida-Core Corporation

Palm City, Florida, USA

Tel: (561) 287-6464

Fax: (561) 287-5373

OCM Test Laboratory

3883 E.Eagle Drive

Anaheim, CA 92807, USA

Tel: (714) 630-3003

Fax: (714) 630-4443

Peak Innovations

11372 W. Parkhill Drive

Littleton, Colorado 80127, USA

Tel: (303) 973-3032

Fax: (303) 972-9720

Plastics Technology Laboratories, Inc.

50 Pearl St.

Pittsfield, MA 01201, USA

Tel: (413) 499-0983

Fax: (413) 499-2339

E-mail: galipeau@plasticstechlabs.com

Practical Composites, Inc.

11 Flint Street

Halifax, Nova Scotia, B3N 2V3, Canada

Tel: (902) 457-9237

Fax: (902) 443-7232

R.A. Schofield Naval Architects

4105 Lake Washington Road

Melbourne, Florida 32934, USA

Tel: (407) 255-8331

Fax: (407) 255-3554

Sigma Labs

6281 39th Street Nth, Suite C

Pinellas Park, Florida 34665, USA

Tel: (813) 526-0331

Fax: (813) 521-4572

(SP Technologies)

Marineware Ltd

Unit 6, Cross House Centre, Cross House Road

Southampton, Hampshire SO14 5GZ , UK

Tel: +44 0 2380 330208

Structural Analysis Inc.

1405 Weston Lane

Austin, TX 78733, USA

Tel: 1-800-388-8134

Structural Composites Inc.

7705 Technology Drive

Melbourne, Florida 32904, USA

Tel: (407) 951-9464

Fax: (407) 928-9071

Society of Naval Architects and Marine Engineers (SNAME)

601 Pavonia Ave.

Jersey City, New Jersey 07306, USA

Tel: (201) 798-4800

Fax: (201) 798-4975

Society for the Advancement and Materials Process Engineering (SAMPE)

1161 Parkview Drive

Covina, California 91724, USA

Tel: (818) 331-0616

Fax: (818) 332-8929

Van Gorkom Yacht Design

49 Fischer Circle

Portsmouth, RI 02871, USA

Tel/Fax: (401) 849-6090