Composite Solutions

Need a strong, lightweight, innovative and cost-effective solution to a structural problem? Van Gorkom Yacht Design offers composite engineering and design services for new projects, modifications, and repairs to existing structures. We specialize in composite analysis and material selection, and laminate scantlings development in compliance with ISO and ABS regulatory requirements.

- New Harbor 28 – outboard bracket

- Voltari 260 – composite design

- Skye 54 (Dove) – “sugar scoop” extension

- Swan 80 – carbon fiber foundations

- Sunfish/Laser Company – tiller head design

- Spirit of Canada – structural laminate

- Corbin 41 – carbon fiber chainplates

- VG-Mount Gay 30 – structural laminate

- Lager 45 – structural laminate & carbon fiber chainplates

- Navy 44 – carbon fiber chainplates & rudder laminate

- Atlantic Boat – structural laminate design

- Tanton 38′ lobster boat – complete composite design

- Dawn 48 – mast bulkhead repair & new chainplates

- Conser 47 – bulkhead repair

- Leadership 44 – structural laminate for hull and deck

- Duffy 42 – hull extension

- Duffy 35 – complete composite design

- J109 – collision repair

- Shelter Island 38 – carbon fiber hardtop

New Harbor Boats, LLC have hired Van Gorkom Yacht Design as their naval architect and structural engineer. Their debut into the powerboat market, the New Harbor 28, was born from the Wasque 26 molds and features a stylish integrated hull extension. VGYD engineered the hull and deck laminate, as well as the composite extension that is subject to significant dynamic loads from the 300hp outboard. The lamination and outfitting of the NH28 is being done by Front Street Shipyard in Belfast, Maine. See New Harbor Boats, LLC for more details.

New Harbor Boats, LLC have hired Van Gorkom Yacht Design as their naval architect and structural engineer. Their debut into the powerboat market, the New Harbor 28, was born from the Wasque 26 molds and features a stylish integrated hull extension. VGYD engineered the hull and deck laminate, as well as the composite extension that is subject to significant dynamic loads from the 300hp outboard. The lamination and outfitting of the NH28 is being done by Front Street Shipyard in Belfast, Maine. See New Harbor Boats, LLC for more details.

Voltari Electric have brought Van Gorkom Yacht Design LLC into their debut project, the Voltari 260, as their composite engineer and naval architect. This all carbon fiber, battery powered, 26ft roadster has a top speed of 70 mph and is whisper quiet. VGYD’s responsibilities have included the engineering of critical carbon fiber components necessary in creating a light-weight boat. In addition, a complete structural analysis of the vessel was conducted for ISO 12215 scantling compliance for potential European markets.

Voltari Electric have brought Van Gorkom Yacht Design LLC into their debut project, the Voltari 260, as their composite engineer and naval architect. This all carbon fiber, battery powered, 26ft roadster has a top speed of 70 mph and is whisper quiet. VGYD’s responsibilities have included the engineering of critical carbon fiber components necessary in creating a light-weight boat. In addition, a complete structural analysis of the vessel was conducted for ISO 12215 scantling compliance for potential European markets.

In 2020, the Lyman Morse Boat Yard in Maine embarked upon a major refit of the Skye 54 “Dove.” VGYD was brought on to design and engineer a hull extension and a new rudder for the boat. A complete 3D modelling and performance evaluation was conducted to verify the added waterline, generated by the “sugar scoop,” enhanced the yacht’s performance. The subsequent glass-work and fairing produced a seamless lengthening of the hull. In addition, an imperceptible watertight access hatch was designed into the existing transom.

In 2020, the Lyman Morse Boat Yard in Maine embarked upon a major refit of the Skye 54 “Dove.” VGYD was brought on to design and engineer a hull extension and a new rudder for the boat. A complete 3D modelling and performance evaluation was conducted to verify the added waterline, generated by the “sugar scoop,” enhanced the yacht’s performance. The subsequent glass-work and fairing produced a seamless lengthening of the hull. In addition, an imperceptible watertight access hatch was designed into the existing transom.

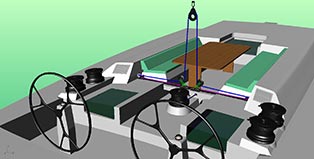

New England Boatworks contracted Van Gorkom Yacht Design to assist in a major refit of a Swan 80. VGYD’s responsibility was to reconfigure the architecture of the yacht’s mainsheet and traveler system, and devise a new jib lead puller and inhauler arrangement. This involved the modelling and engineering of all new carbon fiber foundations that integrated into the existing structure – including sheave boxes, hydraulic ram mounts and the mainsheet bridge and sheeting system.

New England Boatworks contracted Van Gorkom Yacht Design to assist in a major refit of a Swan 80. VGYD’s responsibility was to reconfigure the architecture of the yacht’s mainsheet and traveler system, and devise a new jib lead puller and inhauler arrangement. This involved the modelling and engineering of all new carbon fiber foundations that integrated into the existing structure – including sheave boxes, hydraulic ram mounts and the mainsheet bridge and sheeting system.

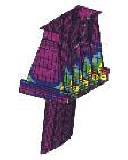

VGYD was contracted by the Sunfish/Laser Company to redesign the tiller head on their Sunfish and Lasers. An extensive structural analysis was conducted to assess the failure mode of the part. The strength of the re-engineered tiller head was confirmed with an FE analysis, verifying the design and the configuration of the new product tooling.

VGYD was contracted by the Sunfish/Laser Company to redesign the tiller head on their Sunfish and Lasers. An extensive structural analysis was conducted to assess the failure mode of the part. The strength of the re-engineered tiller head was confirmed with an FE analysis, verifying the design and the configuration of the new product tooling.

VGYD was contracted by Derek Hatfield to help engineer his Bob Dresser designed Open Class 40 “Spirit of Canada”, which competed in the 2002 Around the World Alone Challenge. The structural design has taken full advantage of the latest composite technology to produce a strong, lightweight, composite structure capable of withstanding the riggers of extreme ocean conditions.

VGYD was contracted by Derek Hatfield to help engineer his Bob Dresser designed Open Class 40 “Spirit of Canada”, which competed in the 2002 Around the World Alone Challenge. The structural design has taken full advantage of the latest composite technology to produce a strong, lightweight, composite structure capable of withstanding the riggers of extreme ocean conditions.

Van Gorkom Yacht Design was hired by Collin Harty, to engineer the composite chainplates for his Corbin 41 “Galene”. In the process of designing the structure for the chainplates a new righting moment curve had to be created and a new rig plan had to configured. The client’s testimonial shows, the experience of building the new chainplates was a very good one. “VGYD was truly a pleasure to work with. They made a concerted effort to understand my intent for the boat and design a solution appropriate to my skill level and technical constraints. VGYD produced the design very quickly, the drawings were detailed and easy to follow, and they provided ongoing follow-up support to make sure fabrication went smoothly.” Click here for more details on Galene.

Van Gorkom Yacht Design was hired by Collin Harty, to engineer the composite chainplates for his Corbin 41 “Galene”. In the process of designing the structure for the chainplates a new righting moment curve had to be created and a new rig plan had to configured. The client’s testimonial shows, the experience of building the new chainplates was a very good one. “VGYD was truly a pleasure to work with. They made a concerted effort to understand my intent for the boat and design a solution appropriate to my skill level and technical constraints. VGYD produced the design very quickly, the drawings were detailed and easy to follow, and they provided ongoing follow-up support to make sure fabrication went smoothly.” Click here for more details on Galene.

The VG30 was designed, engineered and built to the ABS Offshore Racing rule. The boat’s composite structure ensures a high level of strength and hull integrity in anticipation of heavy offshore sailing conditions. The structural design of the VG30 makes widespread use of advanced laminate analysis techniques, and applies them to produce a strong, lightweight, and tough boat. The hull and deck are constructed of wet-preg, epoxy/e-glass laminates over CoreCell foam and end-grain balsa cores, vacuum-bagged and oven-cured for a light and exceptionally strong boat. Local reinforcement with unidirectional fibers and higher density cores is tailored to specific load paths. An ingenious internal grid unit ties together ring frames, stringers, floor timbers, engine bed, maststep and bunk fronts into one integrated structural form to greatly enhance strength and esthetics.

The VG30 was designed, engineered and built to the ABS Offshore Racing rule. The boat’s composite structure ensures a high level of strength and hull integrity in anticipation of heavy offshore sailing conditions. The structural design of the VG30 makes widespread use of advanced laminate analysis techniques, and applies them to produce a strong, lightweight, and tough boat. The hull and deck are constructed of wet-preg, epoxy/e-glass laminates over CoreCell foam and end-grain balsa cores, vacuum-bagged and oven-cured for a light and exceptionally strong boat. Local reinforcement with unidirectional fibers and higher density cores is tailored to specific load paths. An ingenious internal grid unit ties together ring frames, stringers, floor timbers, engine bed, maststep and bunk fronts into one integrated structural form to greatly enhance strength and esthetics.

VGYD has been used exclusively by Rob Ladd Yacht Design for their engineering needs on projects such as the Lager 45, carbon chainplates for the Ladd 53 and the scantlings for the Ladd 48 Power Cruiser. VGYD engineered all the composite structures for the Lager 45 “Wild Woman” to the ABS Offshore Racing Yachts scantling rule. This included carbon fiber chainplates, and an optional lifting keel arrangement. An extensive finite element analysis was conducted to verify the design.

VGYD has been used exclusively by Rob Ladd Yacht Design for their engineering needs on projects such as the Lager 45, carbon chainplates for the Ladd 53 and the scantlings for the Ladd 48 Power Cruiser. VGYD engineered all the composite structures for the Lager 45 “Wild Woman” to the ABS Offshore Racing Yachts scantling rule. This included carbon fiber chainplates, and an optional lifting keel arrangement. An extensive finite element analysis was conducted to verify the design.

Pedrick Yacht Design has out-sourced many of their engineering projects to VGYD including the carbon fiber chainplate system and rudder structures on the United States Naval Academy’s new Navy 44 being built at Pearson Composites in Warren, Rhode Island.

Pedrick Yacht Design has out-sourced many of their engineering projects to VGYD including the carbon fiber chainplate system and rudder structures on the United States Naval Academy’s new Navy 44 being built at Pearson Composites in Warren, Rhode Island.

Maine is the traditional home of the “lobster boat” and one of the premier boat builders of this style is the Atlantic Boat Company of Brooklin who build the famous Duffy & Duffy and BMH line. VGYD have consulted extensively with ABC providing composite engineering allowing them to build strong lightweight structures for an improved powering performance on their D&D 46, D&D 54, and BMH 21.

Maine is the traditional home of the “lobster boat” and one of the premier boat builders of this style is the Atlantic Boat Company of Brooklin who build the famous Duffy & Duffy and BMH line. VGYD have consulted extensively with ABC providing composite engineering allowing them to build strong lightweight structures for an improved powering performance on their D&D 46, D&D 54, and BMH 21.

Tanton Yachts have designed a “lobster boat” styled 38 foot pleasure cruiser to be built in China. VGYD was hired to do the all the composite engineering on the boat including the hull and deck laminate schedule and the internal structure.

Tanton Yachts have designed a “lobster boat” styled 38 foot pleasure cruiser to be built in China. VGYD was hired to do the all the composite engineering on the boat including the hull and deck laminate schedule and the internal structure.

The boatyard where this Frers designed yacht is kept contacted VGYD after the boat lost its rig. We were able to specify an effective repair by strengthening the mast bulkhead with uni-directional material, and its attachment to the hull and deck with bi-direction e-glass. We then designed a completely new configuration for the stainless steel chainplates. The work was done by New England Shipyard.

The boatyard where this Frers designed yacht is kept contacted VGYD after the boat lost its rig. We were able to specify an effective repair by strengthening the mast bulkhead with uni-directional material, and its attachment to the hull and deck with bi-direction e-glass. We then designed a completely new configuration for the stainless steel chainplates. The work was done by New England Shipyard.

When this John Conser designed catamaran suffered structural damage to her main bulkhead during rough weather, the owner sought out the services of Van Gorkom Yacht Design to devise a strong and permanent fix to the problem. To do so, we engineered a comprehensive, bi-directional reinforcing laminate in way of the hull/deck to bulkhead interface.

When this John Conser designed catamaran suffered structural damage to her main bulkhead during rough weather, the owner sought out the services of Van Gorkom Yacht Design to devise a strong and permanent fix to the problem. To do so, we engineered a comprehensive, bi-directional reinforcing laminate in way of the hull/deck to bulkhead interface.

This is the latest yacht design by David Pedrick and Pedrick Yacht Design. The vessel was conceived as an offshore/inshore sail training vessel for the United States Coast Guard Academy but with a performance oriented edge. As such, the fiberglass structure had to be robust yet relatively light. PYD tasked VGYD to engineer a strong and structually efficient e-glass/foam core and vinyl ester resin laminate that met both the ABS scantling rule and was resin-infusion friendly. Morris Yachts in Trenton, Maine are the builders of the vessel and will have delivered 8 boats to the Academy by the end of 2012.

This is the latest yacht design by David Pedrick and Pedrick Yacht Design. The vessel was conceived as an offshore/inshore sail training vessel for the United States Coast Guard Academy but with a performance oriented edge. As such, the fiberglass structure had to be robust yet relatively light. PYD tasked VGYD to engineer a strong and structually efficient e-glass/foam core and vinyl ester resin laminate that met both the ABS scantling rule and was resin-infusion friendly. Morris Yachts in Trenton, Maine are the builders of the vessel and will have delivered 8 boats to the Academy by the end of 2012.

Van Gorkom Yacht Design was contracted by the owner of this Duffy 42 to assist in the extension of the hull and deck to 45 feet. We engineered the new structure and the mechanisims to help scarf the existing and new laminates together so as to maintain the structural integrity of the vessel. The project was done by Ron Jones of Smart Fiberglass in Seattle, WA.

Van Gorkom Yacht Design was contracted by the owner of this Duffy 42 to assist in the extension of the hull and deck to 45 feet. We engineered the new structure and the mechanisims to help scarf the existing and new laminates together so as to maintain the structural integrity of the vessel. The project was done by Ron Jones of Smart Fiberglass in Seattle, WA.

When the Atlantic Boat Company was approached by a client to build a light weight Duffy 35 so that he could put larger engines into the boat, ABC contacted Van Gorkom Yacht Design about re-engineering the laminate schedule for the boat using a combination of carbon fiber, bi-axial e-glass and foam core.

When the Atlantic Boat Company was approached by a client to build a light weight Duffy 35 so that he could put larger engines into the boat, ABC contacted Van Gorkom Yacht Design about re-engineering the laminate schedule for the boat using a combination of carbon fiber, bi-axial e-glass and foam core.

Sail boat racing on Long Island Sound is extremely competitive and sometimes collisions can occur. When this J109 was t-boned the owner called in VGYD to survey the damage and come up with a repair to the hull laminate, as well as oversee the repairs. The work was done at the McMichaels Boat Yard in Mamaroneck New York.

Sail boat racing on Long Island Sound is extremely competitive and sometimes collisions can occur. When this J109 was t-boned the owner called in VGYD to survey the damage and come up with a repair to the hull laminate, as well as oversee the repairs. The work was done at the McMichaels Boat Yard in Mamaroneck New York.

VGYD was approached by CH Marine on Long Island, NY to design a new a “café style” hard top for their 38’ Shelter Island Runabout. The brief called for a geometry that would emulate a soft top, while having all the advantages of a hard top. In addition, the new hardtop had to be easily removable and not impact the performance of the yacht, so it had to be lightweight. Operating under this criteria, and a tight time frame, VGYD was able to develop and model an aesthetically pleasing shape that integrated seamlessly into the existing structures. VGYD worked expeditiously to create a carbon fiber laminate schedule and construction drawings, which enabled the builder to complete the job on time. CH Marine plans to offer this hardtop as an option to future and existing owners of the Shelter Island 38. More information is available at chmarineyachts.com.

VGYD was approached by CH Marine on Long Island, NY to design a new a “café style” hard top for their 38’ Shelter Island Runabout. The brief called for a geometry that would emulate a soft top, while having all the advantages of a hard top. In addition, the new hardtop had to be easily removable and not impact the performance of the yacht, so it had to be lightweight. Operating under this criteria, and a tight time frame, VGYD was able to develop and model an aesthetically pleasing shape that integrated seamlessly into the existing structures. VGYD worked expeditiously to create a carbon fiber laminate schedule and construction drawings, which enabled the builder to complete the job on time. CH Marine plans to offer this hardtop as an option to future and existing owners of the Shelter Island 38. More information is available at chmarineyachts.com.