Project Detail

| Specifications: | ||

|---|---|---|

| LOA | 9.597 m | (31′ 6″) |

| LWL | 9.000 m | (29′ 6″) |

| Max Beam | 3.330 m | (10′ 11″) |

| Draft 1 | 1.950 m | (6′ 5″) |

| Draft 2 | 2.154 m | (7′ 1″) |

| DSPL 1 | 2313 kgs | (5150 lbs) |

| DSPL 2 | 2109 kgs | (4650 lbs) |

| SA (up) | 66 m2 | (710 ft2) |

| SA (dn) | 136 m2 | (1464 ft2) |

Check out the VG30 MK2 (kit-plans) – ideal for the amateur or professional boatbuilder!

The tooling for the VG-Mount Gay 30 is available to lease or to purchase. Contact us for details.

Design Philosophy

It’s no secret… boat owners are tired of paying big bucks to go sailboat racing in something that does not deliver on performance. That, combined with constantly trying to fill crew numbers, is forcing a lot of people out of the sport altogether.

It’s no secret… boat owners are tired of paying big bucks to go sailboat racing in something that does not deliver on performance. That, combined with constantly trying to fill crew numbers, is forcing a lot of people out of the sport altogether.

The VG-Mount Gay 30 is the affordable solution. It’s not only a high performance grand prix racer and a versatile yacht to compete at the local club level, but also the latest generation of boat designed to the Mount Gay 30 Rule. The boat has a unique dual purpose, catering to short handed offshore sailing with water ballast, and around-the-buoys inshore competition with a full crew.

The underlying theme of this project has been one of meticulous consideration to the sailing criteria of the boat. This included an extensive research and development program by Van Gorkom Yacht Design. This effort, coupled with custom quality construction by Boston Boat Works, has delivered a champion fleet racer to the marketplace, not soon to be outclassed by the competition.

Research & Development

To aid in the design process of the VG-Mount Gay 30, Van Gorkom Yacht Design undertook an unprecedented research and development program. This program was comprised of three phases: model development by way of a complete parametric analysis; a one-model tank test series; and a post analysis and optimization to formulate the final set of lines for the production female tooling.

To aid in the design process of the VG-Mount Gay 30, Van Gorkom Yacht Design undertook an unprecedented research and development program. This program was comprised of three phases: model development by way of a complete parametric analysis; a one-model tank test series; and a post analysis and optimization to formulate the final set of lines for the production female tooling.

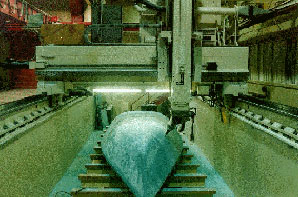

A complete parametric analysis based on a range of 30 footers with similar performance criteria to the VG-Mount Gay 30 was made to develop the lines for the tank test model. The lines were created using an advanced lines-fairing program facilitating the creation of a truly fair hull shape. The resulting computer model was given to the builders for the 5-axis milling of the model hull.

The model was built to a 2/3 scale (approximately 7 meters); the large scale insuring the best possible results for the data collected. Since only one model was being tested with no keel and rudder variations, it was imperative that the resistance curves being generated be as realistic as possible. Approximately 150 runs were made in the towing tank at various speeds, heel angles, yaw angles and rudder angles. This information was used to create a matrix of data that modeled the hydrodynamic characteristics of the hull form. This matrix was in turn used as an effective tool for the calibration of the VPP and ultimately in defining the final hull form.

This proprietary module, written into the VPP, allowed VGYD to simulate the same performance characteristics of the physical tank model. This made it possible to quantify hull variations in terms of performance by racing the variants against the base boat in the VPP. Armed with this powerful analytical tool, a systematic series of canoe body variations was created to allow VGYD to fine tune the hull form resulting in what was considered to be the best performing boat.

An extensive post-analysis was conducted to compare experimental performance data with known performance criteria from other similarly sized yachts (i.e. ILC30s, existing Mount Gay 30s, and the Mumm30). In virtually every instance, the VG-Mount Gay 30 showed itself to be as fast, or faster than the competition, confirming the speed potential of the design. This high-tech approach taken by Geoffrey Van Gorkom has yielded a wealth of knowledge and insight into the performance characteristics of the VG-Mount Gay 30. It not only serves to validate the design; it translates into winning boats for the people who sail them.

Tank Testing the VG-Mount Gay 30

The tank testing has been an essential part of the research and development phase of the program. It has told the designers exactly how the boat is performing and the magnitude of the hydrodynamic force or resistance that is generate by the hull form.

The tank testing has been an essential part of the research and development phase of the program. It has told the designers exactly how the boat is performing and the magnitude of the hydrodynamic force or resistance that is generate by the hull form.

Tooling considerations will affect the method, speed and cost of manufacturing, and so impact on the unit price and market efforts. Tooling must be economical, accurate within the desired tolerances, be easily maintained and repaired, and last the required number of production cycles.

The model was built to a 2/3 scale, approximately 7.0 meters and 1000 kg of displacement. Building a large model such as this has several benefits. Firstly, the optimum weight for the dynamometer is 1000kgs, meaning the best possible results are achievable without having to use counter balances and risk inducing extraneous errors. Also, the greater the scaling factor the cleaner the data will be with a higher degree of repeatability.

These factors had a direct bearing on the overall economics of the program. Since only one model was being tested with no foil variations, and approximately 150 runs being made in the towing tank, it was imperative that the resistance curves generated be as realistic and as accurate as possible so they can be used as an effective tool for the calibration of the VPP and ultimately in defining the final hull form.

The tank testing was conducted at the National Research Council’s Institute for Marine Dynamics in St. John’s, Newfoundland. This facility is regarded as one of the pre-eminent marine research facilities in the world, boasting a 200 meter towing tank, and an extremely accurate and fully calibrated dynamometer for the measurement of lift and drag forces. The tank is also equipped with a sophisticated towing carriage which travels up to 10 meters per second and a hydraulically driven wavemaker capable of generating up to a wave height of one meter.

The tank testing was conducted at the National Research Council’s Institute for Marine Dynamics in St. John’s, Newfoundland. This facility is regarded as one of the pre-eminent marine research facilities in the world, boasting a 200 meter towing tank, and an extremely accurate and fully calibrated dynamometer for the measurement of lift and drag forces. The tank is also equipped with a sophisticated towing carriage which travels up to 10 meters per second and a hydraulically driven wavemaker capable of generating up to a wave height of one meter.

The dynamometer was designed and built by Institute personnel specifically for America’s Cup Research. For more than a year, Fluid Thinking Pty, the design team responsible for Australia One, collaborated with IMD in preparation for the 1995 Americas Cup. The unique precision achieved through its use has resulted in a physical phenomena previously unappreciated by the international hydrodynamics community. This discovery has intern led to improvements in the accuracy of experimental predictions and repeatability of results for yacht hull design.

Post Analysis & Optimization

The data collected from these experiments has allowed the designers to calibrate their VPP, and to run a series of variants to fine tune the resulting hull form. The goal was to create a computer model with the same performance characteristics as what the tank test model exhibited at IMD. This made it possible to make minor changes to the computer model and assess those changes by running the variants against the base boat in the velocity prediction program.

The data collected from these experiments has allowed the designers to calibrate their VPP, and to run a series of variants to fine tune the resulting hull form. The goal was to create a computer model with the same performance characteristics as what the tank test model exhibited at IMD. This made it possible to make minor changes to the computer model and assess those changes by running the variants against the base boat in the velocity prediction program.

Six systematic series were created with each series exploring different parameters such as; the beam to draft ratio, prismatic coefficient, slight changes in the after body, flare variations, and combinations of each. A fleet of the best performing variants from each series was then raced in the VPP to come up with the most optimized hull form. By making this final analysis, it has allowed Van Gorkom Yacht Design to enhance and optimize the performance of the boat.

The VPP software that was be used for the post analysis and optimization has been developed by Clay Oliver of Yacht Research International, Inc. This Windows based program, called Winn Design VPP, is a proven state-of the-art performance prediction tool, having been exclusively used by the winning Team New Zealand in the last America’s Cup. Clay Oliver has an impressive history of being on winning design teams. His portfolio includes Stars & Stripes the 12 meter (1987), Stars & Stripes the catamaran (1988), successful Whitbread projects (1994), and Team New Zealand (1995).

Performance & Results

The VG-Mount Gay 30 has been designed for an all-out performance with a clean and elegant hull shape, narrow waterline beam and a low wetted surface. The freeboard overhangs aid in initial stability and allow either crew weight or water ballast to produce a relatively high righting moment, contributing to the boat’s sailing stability. The bow has a fine entrance angle for windward performance and a gentle run aft for planing ability.

The VG-Mount Gay 30 has been designed for an all-out performance with a clean and elegant hull shape, narrow waterline beam and a low wetted surface. The freeboard overhangs aid in initial stability and allow either crew weight or water ballast to produce a relatively high righting moment, contributing to the boat’s sailing stability. The bow has a fine entrance angle for windward performance and a gentle run aft for planing ability.

One of the primary criteria of the VG-Mount Gay 30 is a strong windward performance. This was deemed necessary to make the boat attractive to the U.S. market whose owners typically race windward/leeward courses. This is not to say that the off-the-wind performance has been compromised, as the VPPs show the boat to be a strong all-round performer for both offshore and around-the-cans conditions.

A displacement/length ratio of approximately 112 in sailing condition (98 in measurement condition), make for a powerful and very easily driven canoe body. The projected sail area to displacement ratio of 33 indicates a great heavy air performance and superb planing potential. The VG-Mount Gay 30’s high sail area to wetted surface ratio predicts a superior light air performance. Since the frictional drag on a hull, which predominates at low speeds, is a function of wetted surface, the sail area to wetted surface ratio of a sailboat is indicative of its performance in light air. Where the average for a 30 footer is about 3.5, this design boasts a ratio of approximately 4.0.

In its first two seasons (1998 & 99), the VG-Mount Gay 30 recorded an impressive string of performances in a number of the East Coast’s more prestigious regattas: Team One Offshore Race – 1st in class, 1st overall; Nantucket Gold Regatta – 5th in class; Buzzards Bay Regatta – 1st in class; New England PHRF Championship – 4th in class; American Yacht Club Fall Series – 1st in class; Key West Race Week – 3rd in class; Block Island Race Week – 1st in class.

Construction of the VG-Mount Gay 30

Boston Boat Works, under the capable direction of well known boat builder, Mark Lindsay, bring their expertise in building composite laminates for one- design and performance racing sailboats to the VG-Mount Gay 30. This design, engineered and built to the Mount Gay 30 Rule and ABS, ensures a high level of strength and hull integrity in anticipation of heavy offshore sailing conditions. The structural design of the VG-Mount Gay 30 makes widespread use of advanced laminate analysis techniques, and applies them to produce a strong, lightweight, yet durable boat.

Boston Boat Works, under the capable direction of well known boat builder, Mark Lindsay, bring their expertise in building composite laminates for one- design and performance racing sailboats to the VG-Mount Gay 30. This design, engineered and built to the Mount Gay 30 Rule and ABS, ensures a high level of strength and hull integrity in anticipation of heavy offshore sailing conditions. The structural design of the VG-Mount Gay 30 makes widespread use of advanced laminate analysis techniques, and applies them to produce a strong, lightweight, yet durable boat.

The hull and deck are constructed of wet-preg, epoxy/e-glass laminates over CoreCell SAN and end-grain balsa cores, vacuum-bagged and oven-cured for a light and exceptionally strong boat. Local reinforcement with unidirectional fibers and higher density cores is tailored to specific load paths.An ingenious internal grid unit ties together ring frames, stringers, floor timbers, engine bed, maststep and bunk fronts into one integrated structural form to greatly enhance strength and esthetics.

Rig & Sails

The competition fractional rig from Hall Spars has in-line jumpers and 15o swept back spreaders. For fine tuning sail shape adjustments there is a 16:1 backstay, checkstay controls, course/fine main sheet controls, and runners with dedicated winches, all within reach of the mainsail trimmer.

The competition fractional rig from Hall Spars has in-line jumpers and 15o swept back spreaders. For fine tuning sail shape adjustments there is a 16:1 backstay, checkstay controls, course/fine main sheet controls, and runners with dedicated winches, all within reach of the mainsail trimmer.

The spars are aluminum alloy with a carbon fiber package option. The specially designed carbon fiber spinnaker pole can be rigged on the mast for symmetric spinnakers, or affixed on the deck in the bowsprit position for a user-friendly asymmetric set. This ensures optimum reaching and downwind performance in all conditions.

There is a high aspect ratio, large roached mainsail of 36m2 (387.5ft2). There are three jibs, 80%, 100%, 150%, ensuring a strong windward performance in all conditions. The 93m2 (1000ft2) 0.5oz masthead asymmetric, and the 0.75oz 100m2 (1076ft2) symmetric spinnakers make for a powerful off-the-wind inventory. A smaller 1.5 oz. asym can be flown from the hounds in heavier conditions.

Basic Rig Measurements of the VG-Mount Gay 30:

I = 11.400m, P = 12.600m, J = 3.480m, E = 4.310m, BAS = 1.475m, SPL = 3.900m

Deck Arrangement

The VG-Mount Gay 30 deck is the perfect working platform for both offshore and around the buoys racing. The cockpit is long and open with ample room for crew to carry out maneuvers. Input from several world champion racers and hardware experts contributed to the selection and placement of hardware and control lines, reflecting the thinking of today’s best racing programs. The Harken grand prix hardware package includes two dedicated runner winches, two primary winches, and two self-tailing Quatro winches on the cabin house.

The VG-Mount Gay 30 deck is the perfect working platform for both offshore and around the buoys racing. The cockpit is long and open with ample room for crew to carry out maneuvers. Input from several world champion racers and hardware experts contributed to the selection and placement of hardware and control lines, reflecting the thinking of today’s best racing programs. The Harken grand prix hardware package includes two dedicated runner winches, two primary winches, and two self-tailing Quatro winches on the cabin house.

The ideal layout conceived for short-handed racing also translates into a very “cruising friendly” configuration. Leads are easily accessible from the safety of the cockpit, and foot braces are placed to ensure both racers and cruisers enjoy a comfortable seating position at any angle of heel. The coach roof has slightly more than the minimum height and area, conforming to the IMS interior volme requirement. This provides a good working area both above and below decks, as well as producing an esthetically pleasing profile.

The ideal layout conceived for short-handed racing also translates into a very “cruising friendly” configuration. Leads are easily accessible from the safety of the cockpit, and foot braces are placed to ensure both racers and cruisers enjoy a comfortable seating position at any angle of heel. The coach roof has slightly more than the minimum height and area, conforming to the IMS interior volme requirement. This provides a good working area both above and below decks, as well as producing an esthetically pleasing profile.

The competition style tiller steering is familiar to the racing helms-person and does not divide the cockpit. The bridge deck, at the forward end of the cockpit, provides an express lane for crew during tacks, keeps the cockpit clear for the trimmers, increases headroom below, and provides some comfortable seating when enjoying leisurely afternoon sails.

Interior Arrangement

The interior of the VG-Mount Gay 30 has a very attractive and clean finish. It is functional and well attuned to offshore sailing and coastal cruising. In the central cabin there is a comfortable sitting height of 1.60m (5.5ft) over a length of 2.05m (6.73ft).

The interior of the VG-Mount Gay 30 has a very attractive and clean finish. It is functional and well attuned to offshore sailing and coastal cruising. In the central cabin there is a comfortable sitting height of 1.60m (5.5ft) over a length of 2.05m (6.73ft).

There are four fixed berths 1.9m (6.23ft in length), port and starboard, two in the central cabin and two aft quarter berths. The galley, forward and to port, has a sink and a one-burner stove and plenty of counter top. There is stowage both underneath the working space and outboard of it.

To starboard there is a removable cooler, the top of which forms additional counter space. There is storage lockers outboard and cubby holes port and stbd for odds and ends. Aft of the companionway is a dedicated nav station with a full instrument console. The mast bulkhead separates the head from the main cabin. Fresh water capacity is 14 gals, located in a bladder tank under the galley sink. The fuel tank, located just aft of the engine, has a capacity of 15 gal. The inboard Yanmar diesel with Saildrive unit is immediately aft of the companionway ladder. In the forward compartment of the engine box is a 75 amp hour battery.

To starboard there is a removable cooler, the top of which forms additional counter space. There is storage lockers outboard and cubby holes port and stbd for odds and ends. Aft of the companionway is a dedicated nav station with a full instrument console. The mast bulkhead separates the head from the main cabin. Fresh water capacity is 14 gals, located in a bladder tank under the galley sink. The fuel tank, located just aft of the engine, has a capacity of 15 gal. The inboard Yanmar diesel with Saildrive unit is immediately aft of the companionway ladder. In the forward compartment of the engine box is a 75 amp hour battery.

Foil Configuration

The keel is a state-of-the-art, high-lift foil and dolphin bulb configuration and is designed to the maximums limits of the Mount Gay 30 Rule. It has a draft of 1.95m (6.4ft) with a keel weight of 1150kgs (2535 lbs) giving the boat a ballast to weight ratio of 50%. This, together with movable ballast, provides the VG-Mount Gay 30 with a powerful righting moment.

The keel is a state-of-the-art, high-lift foil and dolphin bulb configuration and is designed to the maximums limits of the Mount Gay 30 Rule. It has a draft of 1.95m (6.4ft) with a keel weight of 1150kgs (2535 lbs) giving the boat a ballast to weight ratio of 50%. This, together with movable ballast, provides the VG-Mount Gay 30 with a powerful righting moment.

Two keel options are available with this design. The first is the Mount Gay 30 Class legal keel, as previously described. The second is a “sports” keel that is 200mm (8″) deeper and 225 kgs (500 lbs) lighter, essentially making for a lighter boat but with a similar righting moment. These keel options add yet another dimension of versatility to the VG-Mount Gay 30. The structural components of the keel comprise of a ductile iron keel to hull flange and fin insert, with an integrally cast lead fin and bulb. The keel flange is faired into a recess in the hull, which provides maximum strength and rigidity and easily detaches for trucking.

The pre-preg all-carbon rudder and rudder post are exceptionally light with weighing only 9 kgs (20 lbs). The high lift sections of the rudder are similar and complimentary with that of the keel foil. The elliptical trailing edge maximizes effectiveness and minimizes drag. Harken Black Magic rudder bearings complete the feeling of smooth and virtually frictionless helm control. Like the keel, the rudder is easily detached for ease of transportation.

Water Ballast

When racing offshore, sailing shorthanded, or just cruising, a full range of stability is available using the water ballast tanks. This added righting moment gives the VG-Mount Gay 30 a marked performance increase, and is a proven, safe and reliable form of movable ballast.

The system operates via an electric pump with a hand pump backup. The pump may be brought on line at any time and takes approximately two minutes to fill a tank. The flow controls are located in the cockpit just forward of the traveler, providing quick and convenient access to the trimmer. The total capacity of the port and starboard wing tanks is 600 liters (158.5 gals), or the weight of three and a half crew members per side.

The plumbing of the tanks is designed to be simple, easy to maintain, yet highly efficient. There are only three flow controls to this system; the 3″ dia. inlet/outlet gate valve, and two port and starboard gate valves for the 3″ dia transfer pipe. Two-way diverter valves are located down below to switch from a bilge pickup, or to switch from the engine pump to the hand pump. The gate valves are all spring-loaded (+ in the closed position) with control lanyards leading up into the cockpit which can be held open by cam-cleating the lanyard in place.

Operating the water ballast system couldn’t be easier. To pump water into the port tank, the starboard and overboard gate valves are closed. Begin pumping until the port breather valves, located on the shear, blow water. To dump the water ballast, simply open the port and overboard gate valves, and the water will drain out with gravity. Tacking the VG-Mount Gay 30 with water ballast is just as easy. Prior to the tack, open both port and starboard gate valves, keeping the overboard gate valve closed, so the water will drain down to the lower tank. The transfer, with the 3″ transfer pipe, takes approximately 30 seconds. Once the transfer is complete, close both gate valves and tack. It’s almost like roll tacking the boat! If there is any water loss, the new windward tank can be easily topped up with a few strokes on the hand pump.

Transportation of the VG-Mount Gay 30

The VG-Mount Gay 30 can be set up and rigged in under two hours, and launching from a single-point hoist takes only 15 minutes. The towing package includes a state-of-the-art Triad Trailer, complete with electric brakes, hull saddles, and a dock box. This makes transporting the boat from regatta to regatta a breeze. There’s no better delivery than 55mph to windward down the highway.

The VG-Mount Gay 30 can be set up and rigged in under two hours, and launching from a single-point hoist takes only 15 minutes. The towing package includes a state-of-the-art Triad Trailer, complete with electric brakes, hull saddles, and a dock box. This makes transporting the boat from regatta to regatta a breeze. There’s no better delivery than 55mph to windward down the highway.